We Handcraft

At Moka Origins each step of our chocolate-making process is carefully calculated, from cacao bean to the finished chocolate bar. So you might be asking, what do we mean by “craft chocolate”? There are over 300 craft chocolate makers in the U.S.! Many of these pay premium prices for the cacao beans they buy, ensuring cacao farmers earn a sustainable living wage. We take craft chocolate one step further and use organic beans, grown without pesticides and herbicides. Moka Origins plants 1 tree for every chocolate bar sold. To date, our farmers have planted more than 500,000 fruit and shade trees on their land holdings.

In this article we will explore all the moves it takes to make our signature flavor-forward bars of chocolate. Count the number of handling steps it takes along the craft chocolate journey and you will see what we mean by handcrafted, bean-to-bar chocolate.

Grow

Cacao pods are a fruit that grow on trees in tropical regions of the world. The beans that are inside of these pods are what we use to make chocolate, but they have to undergo quite the transformation first. Cacao pods come in a variety of colors and flavors. These flavors depend on where and how the cacao is grown, including factors like altitude, climate, and surrounding vegetation. Cacao beans from one region might taste tart and fruity once roasted, while from another region they may be more nutty and earthy. These unique flavors find expression in the final chocolate, and you will be able to taste the difference between beans from different origins.

Harvest

Cacao farmers hand harvest the ripe pods; cacao pods come in a variety of colors including red, orange, purple, yellow, and green. Unlike many fruits, cacao pods grow directly out of the trunk. Farmers carry the pods to a central point where they can extract the fresh beans.

Open

Farmers split the cacao pods open and scoop out the cacao beans. There are about 20-40 beans in each pod. The cacao beans are covered in a white sugary pulp, which tastes a bit like lemonade.

Ferment

Fresh cacao beans are loaded into wooden crates to ferment for 6-7 days. Cacao workers stir the beans and check internal temperatures to ensure a proper fermentation. The sugar in the pulp is food for the microbes that cause fermentation. They consume the sugar and produce lactic acid. This process is crucial in the flavor development of cacao beans, and plays a significant role in the taste of the final chocolate. Without fermentation, our chocolate would not taste anything like it does. Fermented beans are checked for a color change, from purple to brown.

Dry

There are several methods to dry cacao beans. Most of our producers use the method of laying out the beans to dry on large wire tables in open-air pavilions. The beans are mixed and turned every day for up to seven days.

Ship and Receive Beans

Once dried, cacao beans are packaged for shipping. Some co-ops gather beans from different farms in the area, others have their own farm that they gather beans from. All of the co-ops and farms we work with pay premiums to the farmers they gather beans from, ensuring it’s worthwhile for farmers. Beans are bagged in large jute sacks which then get shipped overseas to our chocolate factory in Honesdale, Pennsylvania.

Roast and Winnow

Cacao is roasted in a similar way to coffee, but at a lower temperature and about twice as long. Unlike coffee, once roasted, cacao has a way to go before it turns into chocolate. After roasting, the cacao beans are still covered by a husk that must be removed to ensure consistent texture and flavor. This process of removing this husk from the cacao bean is called winnowing. Once complete, only the inside of the bean remains. These are known as “cocoa nibs” and are what we use to make chocolate.

Grind

This is where the real magic begins: transforming cacao nibs into tasty chocolate. Our stone grinders run for 3-4 days (yes really!) per batch to carefully refine the cocoa nibs and organic cane sugar into delicious liquid chocolate. We have a couple of high-speed grinders that enable larger production runs of customer favorites: Blueberry, Cherry, Lemon Ginger, and Sea Salt.

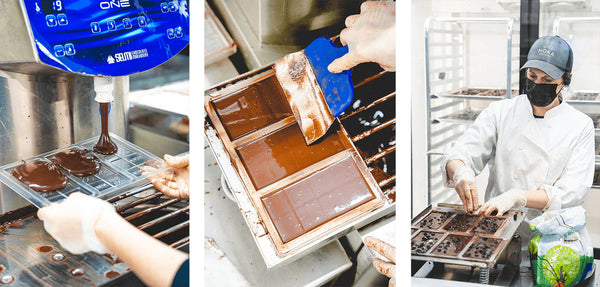

Temper and Mold

Tempering is the process of heating and cooling chocolate so that it crystallizes into a stable form. This gives each bar a beautiful sheen, sharp snap upon breaking, and temperature stability so our chocolate melts on your tongue (not in the wrapper!). In this step, liquid chocolate is poured into molds, and inclusions (such as blueberries) are hand-sprinkled on top.

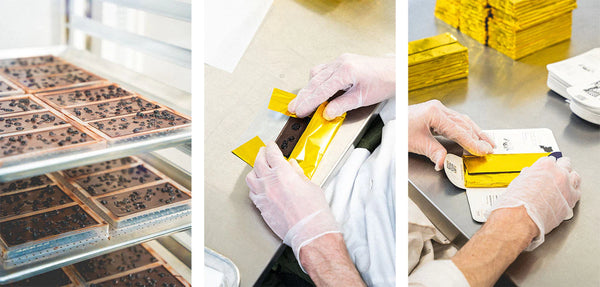

Unmold and Wrap

It takes about 30 minutes for chocolate to cool in the mold. Once cooled, the chocolate can be removed. We then wrap each bar by hand in gold foil, and then hand-wrap in the paper box wrapper. You now have a finished chocolate bar!

Enjoy

Our ethically made craft chocolate is best shared with friends and family. Plan a chocolate-tasting party and try each of our cacao origins. Ready to try the craft chocolate difference? Shop our selection of inclusion bars and single origins.